Improved slow motion control for a C5 as a guidescope

With the old setup the C5 was mounted piggyback on the C9 and could not aimed at a guide star independently from the C9. I designed a lot of constructions but ended up with a slow motion control offered by Celestron, Vixen or Adorama ("ProOptic"). This accessory can be mounted between a tripod and a telescope or a camera and moved azimuthal and in elevation. I ordered the De-Luxe version without having seen it beforehand.

The head of the slow motion control could be moved without play. That was the nice thing. But it looked to me a bit weak to hold a C5 for guiding. The head was to small to hold the C5 and the base had to be mounted with just one screw. That could not work under load.

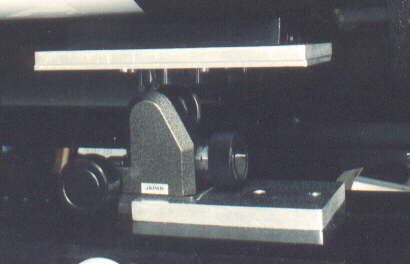

I made a horse-shoe type plate around the base of the slow motion control and bolted it to the Losmandy mounting plate. Now pivoting of the whole thing was impossible. As the next thing I made a larger head from two aluminium plates to carry the C5. I cut a rectangular hole in the top plate that fit around the head of the slow motion control. The lower plate got a cut-out to got around the support of the head. Both plates got two holes for bolting the C5 to the plates.

The result can be seen in the picture above. The C5 could be turned about +/- 10° in borth axes compared to the C9. Carrying the big C5 the slow motion control still looked flimsy. And it was, especially the elevation control. The whole thing had to become beefier. That would be a tough job because there was not much space and the knobs for turning had be reached easily.

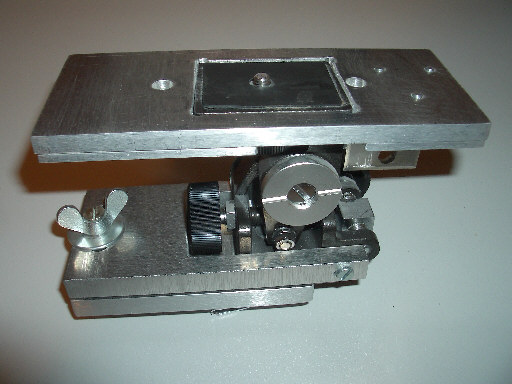

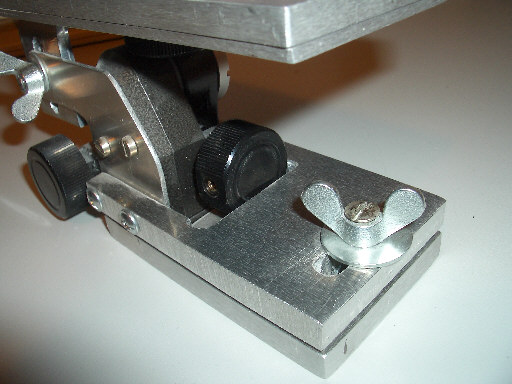

I solved the problem by bolting a hooked sheet to the lower arm of the slow motion control. Another small aluminium sheet was bent 90° and bolted to the upper mounting plate. A bolt can move in a curved slit and be locked by a winged nut to prevent any movement in elevation. Next I made another horse-shoe type plate around the lower arm of the slow motion control. This plate got a curved slit. The plate beneath a threaded hole. A washer ensures a small distance of the two plates. Now I could lock the upper plate with a winged bolt to the lower plate around the base of the slow motion control. After unlocking the winged nuts and bolts I can move the axes of the slow motion control, after locking them again the C5 stays put.

The whole thing appears to be rock steady. Will it be that in the field? The following pictures show more details of the improved slow motion control.

Addendum:

Meanwhile I could test the improved slow motion control in the field. It turned out that it has to be improved even further. The problem is that the knob for the elevation control cannot easily be reached and powerful turned. This is even a bigger problem when the heavy C5 is mounted to the slow motion control and aimed at objects higher then 45° above the horizon. I have already an idea for a solution. It only has to be realized.